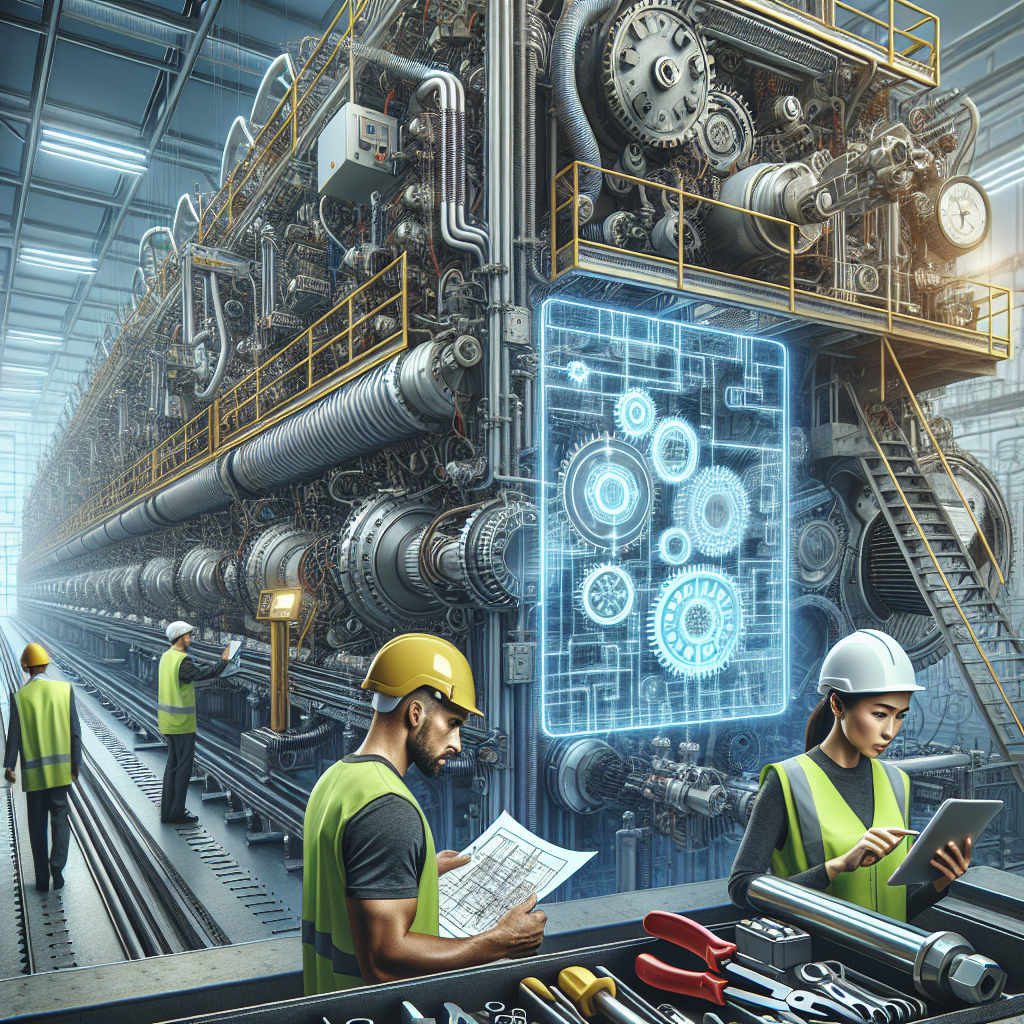

In the fast-paced world of industrial automation, the key to smooth operation lies in meticulous maintenance. From advanced robotics to intricate control systems, every component plays a crucial role in maximizing productivity and efficiency. In this comprehensive guide, we delve deep into the intricacies of industrial automation system maintenance, exploring the various tools, techniques, and best practices to keep your operations running seamlessly. From preventive maintenance schedules to troubleshooting common issues, this guide is your go-to resource for ensuring the smooth functioning of your automation systems. Join us on this journey as we uncover the essential steps to maintaining peak performance in the dynamic world of industrial automation.

Understanding the Fundamentals of Industrial Automation Systems

Industrial automation systems are sophisticated networks of machinery, software, and control systems designed to streamline and optimize manufacturing processes. These systems typically consist of the following components:

- Sensors: Devices that gather data from the physical environment, such as temperature, pressure, or motion.

- Programmable Logic Controllers (PLCs): Industrial computers that execute specific tasks based on the input from sensors.

- Human Machine Interfaces (HMIs): Interfaces that allow operators to interact with and monitor the automation system.

- Actuators: Devices that carry out physical actions based on signals from the PLCs, such as opening or closing valves.

Maintenance is crucial in industrial automation systems to ensure smooth operation and prevent downtime. Regular maintenance helps identify and address issues before they escalate, leading to optimal system performance and longevity. By understanding the components and functions of automation systems, maintenance teams can effectively diagnose problems and implement necessary solutions to keep the system running efficiently.

Common Maintenance Practices for Industrial Automation Systems

Regular Inspection and Monitoring

Regular inspection and monitoring are fundamental aspects of maintaining industrial automation systems. This proactive approach helps in identifying potential issues before they escalate into major problems, minimizing downtime, and ensuring optimal system performance. Key considerations in this practice include:

-

Scheduled Checks: Establishing a routine schedule for inspections is crucial to staying ahead of potential malfunctions. This could include daily, weekly, monthly, and annual checks based on the system’s complexity.

-

Component Examination: During inspections, it is essential to focus on key components such as sensors, actuators, controllers, and communication interfaces. Checking for signs of wear and tear, loose connections, or abnormal readings can help prevent sudden breakdowns.

-

Software Updates: Monitoring software health and ensuring timely updates is equally important. Keeping abreast of the latest firmware releases and patches can enhance system security and functionality.

-

Documentation: Maintaining detailed records of inspection findings, repairs, and maintenance activities is essential for tracking the system’s health over time. This documentation can also aid in troubleshooting recurrent issues.

-

Performance Analysis: Regular monitoring of system performance metrics, such as cycle times, error rates, and energy consumption, can provide valuable insights into the system’s overall health. Deviations from established benchmarks can signal underlying problems that require attention.

By incorporating regular inspection and monitoring practices into the maintenance routine, industrial automation systems can operate efficiently and reliably, contributing to increased productivity and cost savings.

Preventive Maintenance Strategies

Common Maintenance Practices for Industrial Automation Systems

Preventive maintenance strategies are crucial in ensuring the optimal performance and longevity of industrial automation systems. By implementing proactive measures, companies can significantly reduce the risk of unexpected system failures, downtime, and costly repairs. This proactive approach involves regular inspections, testing, and adjustments to identify and address potential issues before they escalate into major problems. Scheduled maintenance tasks play a vital role in preventive maintenance, as they help in the early detection of wear and tear, faulty components, or performance degradation. Regularly scheduled maintenance tasks can include:

-

Routine Inspections: Conducting visual inspections of equipment, components, and connections to identify any signs of wear, corrosion, or damage.

-

Cleaning and Lubrication: Keeping the system clean and properly lubricated to prevent friction, overheating, and premature component failure.

-

Calibration Checks: Verifying the accuracy and consistency of sensors, actuators, and other critical components to maintain optimal system performance.

-

Software Updates: Ensuring that the system’s software is up to date with the latest patches, bug fixes, and security enhancements to prevent vulnerabilities and malfunctions.

-

Backup and Recovery Procedures: Implementing regular data backups and recovery protocols to protect critical system configurations, programs, and operational data.

Troubleshooting Techniques for Industrial Automation Systems

Identifying Common Issues

Troubleshooting Techniques for Industrial Automation Systems

- Power Supply Problems

- Voltage fluctuations causing system failures

- Overloading circuits leading to shutdowns

-

Inadequate grounding resulting in erratic behavior

-

Communication Failures

- Network issues causing data loss

- Protocol mismatches disrupting operations

-

Faulty connections impeding information flow

-

Mechanical Breakdowns

- Worn-out components affecting system performance

- Misaligned parts causing malfunctions

-

Lack of lubrication leading to equipment failure

-

Software Glitches

- Bugs in the programming impacting system functionality

- Compatibility issues with updates or new software

-

Incorrect configurations causing errors

-

Sensor Malfunctions

- Dirty or damaged sensors providing inaccurate data

- Misaligned sensors triggering false alarms

-

Wiring issues leading to sensor failures

-

Human Errors

- Improper training resulting in incorrect system usage

- Neglecting maintenance schedules leading to issues

- Unauthorized modifications causing system instability

Implementing Corrective Measures

-

Identifying the Root Cause: Before implementing corrective measures, it is crucial to identify the root cause of the malfunction in the industrial automation system. This may involve conducting thorough diagnostics, analyzing error logs, and consulting system documentation.

-

Developing a Repair Plan: Once the root cause is pinpointed, a detailed repair plan should be developed. This plan should outline the specific steps and resources needed to address the issue effectively. It is essential to consider factors such as equipment availability, expertise required, and potential impact on production.

-

Executing Repairs: With the repair plan in place, the next step is to execute the repairs promptly and accurately. This may involve replacing faulty components, reconfiguring software settings, or recalibrating sensors. It is essential to follow established procedures and safety protocols to ensure the integrity of the automation system.

-

Testing and Validation: After implementing corrective measures, thorough testing and validation are necessary to verify that the issue has been resolved. This may include running diagnostic tests, simulating production scenarios, and monitoring system performance. Any discrepancies or anomalies should be addressed promptly to prevent further malfunctions.

-

Documentation and Reporting: Finally, it is essential to document all repair activities and outcomes for future reference. This documentation should include details such as the nature of the malfunction, steps taken to address it, and any lessons learned during the process. Reporting on the maintenance activities can help improve future troubleshooting efforts and contribute to overall system reliability.

Software Updates and Security Measures in Industrial Automation

Importance of Software Updates

-

Enhanced Performance: Regular software updates in industrial automation systems help enhance overall performance by improving system efficiency, speed, and reliability. Updates often include bug fixes and optimizations that can streamline operations and reduce downtime.

-

Security Enhancements: Keeping automation software up to date is crucial for maintaining robust cybersecurity measures within industrial environments. Updated software often includes the latest security patches to protect against evolving cyber threats and vulnerabilities, safeguarding sensitive data and preventing unauthorized access.

-

Compatibility and Integration: Software updates ensure compatibility with new technologies and devices, allowing seamless integration with existing systems. This compatibility is essential for maintaining interoperability and ensuring that all components of the automation system function harmoniously together.

-

Compliance Requirements: Many industries have specific regulatory standards and compliance requirements that necessitate running the latest software versions. Regular updates help ensure that the industrial automation system meets these standards, avoiding potential penalties or legal issues.

-

Sustainability and Longevity: By staying current with software updates, industrial automation systems can prolong their lifespan and remain sustainable in the long term. Updates often include features that support scalability, adaptability to changing business needs, and future-proofing the system against obsolescence.

Enhancing System Security

In the realm of industrial automation, enhancing system security is paramount to safeguarding crucial operations from external threats. This involves a multi-faceted approach that integrates various cybersecurity measures to fortify the system’s defenses.

Implementing cybersecurity measures in industrial automation

- Utilizing robust firewalls and intrusion detection systems to monitor and filter incoming and outgoing network traffic, identifying and thwarting potential cyber threats before they can infiltrate the system.

- Employing encryption protocols to protect sensitive data transmitted within the automation network, ensuring that information remains secure and inaccessible to unauthorized users.

- Conducting regular vulnerability assessments and penetration testing to identify weaknesses in the system’s security posture, enabling proactive remediation to prevent potential breaches.

Protecting sensitive data and preventing unauthorized access

- Implementing strict access control mechanisms, such as user authentication and role-based permissions, to restrict system entry only to authorized personnel, minimizing the risk of unauthorized access to critical components.

- Establishing secure remote access protocols with stringent authentication procedures to enable off-site monitoring and maintenance while maintaining a secure connection that mitigates the risk of cyber intrusions.

- Regularly updating software and firmware to patch known vulnerabilities and enhance system resilience against emerging cyber threats, ensuring that the automation system remains up-to-date and fortified against potential exploits.

Training and Skill Development for Maintenance Personnel

Importance of Training Programs

-

Enhancing Maintenance Efficiency: Training programs play a pivotal role in enhancing the efficiency of maintenance personnel by equipping them with the necessary skills and knowledge to effectively troubleshoot and address issues within the industrial automation system.

-

Reducing Downtime: Properly trained maintenance staff are better equipped to quickly identify and rectify problems, thereby reducing downtime in the production process. This leads to improved overall productivity and cost savings for the organization.

-

Ensuring System Reliability: Through specialized training, maintenance personnel can gain a deeper understanding of the intricacies of the industrial automation system, allowing them to proactively address potential issues before they escalate, thus ensuring the reliability and smooth operation of the system.

-

Adapting to Technological Advancements: Industrial automation systems are constantly evolving with technological advancements. Training programs enable maintenance staff to stay updated with the latest technologies, tools, and techniques, empowering them to effectively maintain and optimize the system in line with industry trends.

-

Enhancing Safety Protocols: Training programs not only focus on technical skills but also emphasize the importance of safety protocols and regulations. Well-trained maintenance personnel are better equipped to perform their tasks in a safe manner, reducing the risk of accidents and ensuring a secure working environment for all employees.

Continuous Learning and Skill Enhancement

In the realm of industrial automation system maintenance, continuous learning and skill enhancement are paramount for maintenance personnel to stay abreast of the rapidly evolving technologies and methodologies. This section delves into the importance of encouraging ongoing education and adapting to new advancements in the field of industrial automation.

- Encouraging ongoing education in automation technologies

- Maintenance personnel should actively seek out training programs, workshops, and seminars that focus on the latest automation technologies relevant to their industry.

- Engaging in online courses or certifications can provide valuable insights into emerging trends and best practices in industrial automation system maintenance.

-

Collaborating with industry experts and participating in knowledge-sharing forums can broaden one’s understanding of complex automation systems and their maintenance requirements.

-

Adapting to new advancements in the field of industrial automation

- Staying informed about technological advancements, such as the Internet of Things (IoT), artificial intelligence (AI), and predictive maintenance, can help maintenance personnel optimize the performance of automation systems.

- Experimenting with new tools and software applications can enhance efficiency and effectiveness in troubleshooting and resolving maintenance issues.

- Embracing a proactive mindset towards learning and adaptation is crucial for maintenance personnel to navigate the intricate landscape of industrial automation system maintenance effectively.

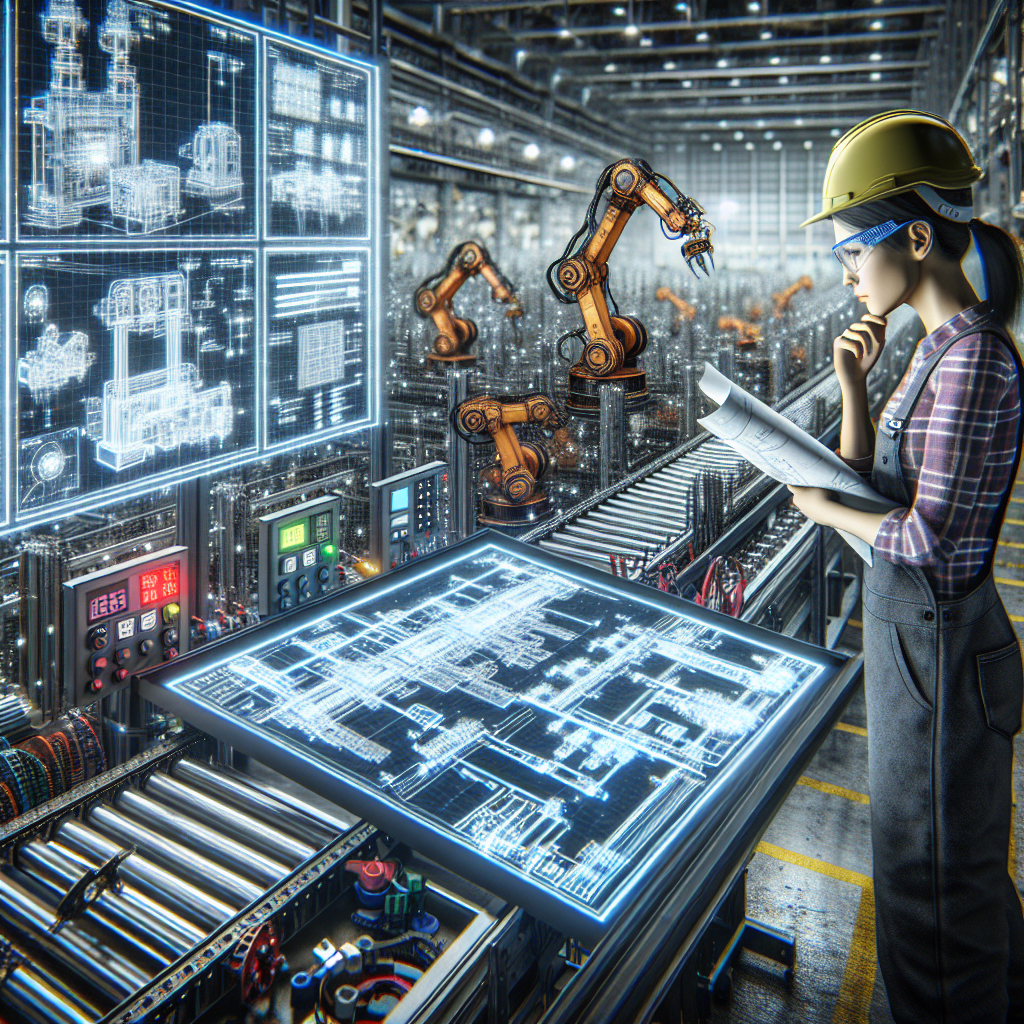

Utilizing Data Analytics for Predictive Maintenance

Role of Data Analytics in Maintenance

- Leveraging data for predictive maintenance strategies

Data analytics plays a crucial role in industrial automation system maintenance by enabling organizations to predict potential issues before they occur. By collecting and analyzing data from various sensors and devices within the system, maintenance teams can identify patterns and trends that indicate possible future failures. This proactive approach allows for timely interventions, reducing downtime and optimizing system performance.

- Using analytics to forecast potential system failures

Predictive maintenance strategies rely on data analytics to forecast potential system failures accurately. By monitoring key performance indicators and historical data, maintenance teams can identify early warning signs of equipment degradation or malfunctions. This foresight enables organizations to schedule preventive maintenance tasks strategically, avoiding costly breakdowns and minimizing disruptions to operations.

Benefits of Predictive Maintenance

- Reducing Downtime and Optimizing System Performance

- Predictive maintenance allows for the identification of potential issues before they lead to system failure, thereby reducing unexpected downtime significantly.

- By proactively addressing maintenance needs based on data analytics, industrial automation systems can operate at peak performance levels consistently, ensuring optimal output and efficiency.

-

The ability to schedule maintenance tasks strategically based on predictive insights minimizes disruptions to production schedules, leading to increased overall productivity.

-

Cost-Effective Maintenance Practices Based on Data Insights

- Predictive maintenance enables organizations to prioritize maintenance tasks according to criticality and urgency, optimizing resource allocation and reducing unnecessary expenses.

- By pinpointing specific components or areas that require attention, predictive maintenance prevents over-maintenance of less critical system elements, resulting in cost savings in the long run.

- The data-driven approach of predictive maintenance also helps in extending the lifespan of industrial automation systems by addressing issues early, thereby reducing the frequency of major repairs or replacements.

FAQs: Exploring the Intricacies of Industrial Automation System Maintenance: A Comprehensive Guide

What is industrial automation system maintenance?

Industrial automation system maintenance refers to the process of ensuring that all the components of an industrial automation system, such as machinery, software, and equipment, are functioning properly and efficiently. This includes regular inspections, troubleshooting, repairs, and upgrades to prevent breakdowns and improve overall productivity.

Why is industrial automation system maintenance important?

Industrial automation system maintenance is crucial for enhancing productivity, reducing downtime, and extending the lifespan of equipment. Regular maintenance helps identify potential issues before they escalate, leading to costly repairs or complete system failures. By ensuring that all components of the automation system are well-maintained, companies can optimize their operations and stay competitive in the market.

What are the common tasks involved in industrial automation system maintenance?

Some common tasks involved in industrial automation system maintenance include routine inspections of machinery and equipment, cleaning and lubricating moving parts, calibrating sensors and controllers, updating software and firmware, monitoring for abnormal behavior, and training staff on proper maintenance procedures. These tasks help prevent malfunctions, improve efficiency, and prolong the lifespan of the automation system.

How often should industrial automation system maintenance be conducted?

The frequency of industrial automation system maintenance varies depending on several factors, such as the type of equipment, the operating environment, and the workload. However, it is generally recommended to perform routine maintenance on a quarterly or biannual basis and schedule more thorough inspections and upgrades annually. Additionally, companies should establish a proactive maintenance schedule based on the specific needs of their automation system to ensure optimal performance and reliability.

What are the benefits of outsourcing industrial automation system maintenance?

Outsourcing industrial automation system maintenance to a third-party service provider can offer several benefits, such as access to specialized expertise, reduced workload on internal staff, improved system performance, and cost savings. Service providers often have the necessary training, tools, and experience to efficiently maintain automation systems, allowing companies to focus on their core business activities. Additionally, outsourcing maintenance can help reduce downtime and ensure that the automation system operates smoothly and reliably.